Cooling

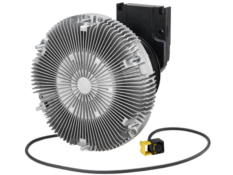

Fan Drives & Clutches

We provide high-quality fan drives and clutches for heavy-duty equipment and vehicles. With a variety of options available, our products are designed to meet the needs of customers in different industries.

Filters

Variable Speed

LCV Series

A live center variable speed fan drive in a light, compact and reliable design features impressive fuel savings, reduced fan noise and more available horsepower.

LCX Series

A durable, live-center fan drive with industry-leading low-speed controllability, low off speed and Cold-Start Disengagement (CSD™) technology, specifically engineered for large off-highway equipment.

RCV High-Horsepower Series

Variable-speed, viscous fan drives designed to provide precision cooling in high-horsepower, off-highway applications.

RCV250

Variable speed with a light, compact and reliable design allows the RCV250 to turn larger fans that require higher torque while maximizing efficiency and requiring zero maintenance.

RCX Series

A bracket-mounted fan drive with industry-leading low-speed controllability, low off speed and Cold-Start Disengagement (CSD™) technology, specifically engineered for heavy- and medium-duty trucks.

VS Air

Viscous fan drive utilizing a bimetal precision sensor which modulates fan speed based on temperature of air through the cooling package.

VS series

Pulse-width-modulation (PWM) signals from the engine management system to this viscous, directly-controlled fan drive makes it responsive to changing cooling requirements.

Two Speed

DM Advantage® Two-Speed

Alternating between eddy-current and spring-actuated cooling to moderate operating noise and increase available horsepower for auxiliary systems. Typical engine horsepower range: Up to 447 kW [600 HP]

MSC2® Multispeed

The MSC2 two-speed design provides optimal cooling in low mode, most of the time, thereby drawing less horsepower. Typical engine horsepower range: up to 375 HP [280 KW].

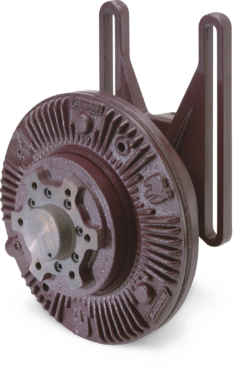

On/Off

DM Advantage On/Off

The DM Advantage On/Off Fan Drive offers a superior solution for some of the highest-heat under-hood applications. Typical engine horsepower range: 186 – 447 KW [250-600 HP]

EC450®/EC600™

The electromagnetically-engaged series offers no-slip operation for quick response to cooling requirements. Typical Engine horsepower range respectively: 37 – 250 KW [50 – 275 HP] and 37 – 205 KW [50 – 275 HP]

HT/S Advantage™

The HT/S provides optimized cooling by reacting to slippage and obstructions.

HT650

Heavy- and medium-duty trucks benefit from the engine-controlled HT650 which engages only when cooling is needed. It provides maximum torque for high-airflow fans without slippage.

Kits Remans

DM Advantage & HT/S Advantage Reman Fan Clutches

The DM Advantage On/Off Fan Clutch offers a superior solution for some of the highest-heat under-hood applications like trucks and buses.

DM Advantage Repair Kits

Horton DM Advantage fan clutch repair kits make things easier at both the parts counter and in the repair bay.

K32 Dual Pilot

The K32 Dual Pilot fan clutch comes with world-class customer service and quality, so even fleets running competitors’ fan drives can experience the Horton advantage.

PolarExtreme HT/S Remanufactured Fan Clutches

The premium remanufactured HT/S Advantage Fan Clutch that is tested for extreme reliability. Includes the new PFD (Piston Friction Disc) and upgraded seal design for a longer life.

Hubs and Tensioners

Fan Drive Hubs

Fully customized. Stronger. More durable. Fan drive hubs from Horton help provide complete engine cooling solutions.

Tensioners

Genuine Horton tensioners are precisely engineered via longstanding accessory design and rotation expertise.