Discover the Benefits of Custom Fan Drives & Fans

At Horton, we understand that every engine and application has unique cooling demands. That’s why we offer custom-engineered fan drives and fans, paired with expert design assistance, to ensure optimal performance, efficiency, and durability.

Here are the key benefits:

1. Precisely Matched Cooling Solutions

Our metal cooling fans are fully customizable: blade configuration, size, pulley ratios, speed range, and shroud type. Each fan is tailored for the exact airflow and operating parameters required.

- Size & configuration: from 15″ to 96″ in diameter, with blade counts ranging from 4 to 11.

- Application-specific design: whether it’s mining, agriculture, generator sets, or heavy-duty trucks, our engineering team crafts solutions for each unique need.

2. Fuel & Energy Savings with Smart Fan Drives

Our custom fan drives, including two-speed, on/off, and variable-speed systems, deliver precise coolant control which minimizes parasitic engine drag to save fuel, reduce noise, and free up horsepower.

- Variable-Speed Options (e.g., RCV, LCV, LCX, VS) modulate fan output in response to cooling demand.

- Two-Speed Options (DM Advantage®, MSC2®) switch between low and high speed to balance efficiency and performance.

- On/Off Models engage cooling only when needed which is perfect for high-heat scenarios.

3. Advanced Composite & Modular Designs

- HTEC Thermoset Composite Fans: engineered for heavy-duty off-highway use, offering metal-like strength, high-speed capacity, corrosion resistance, weight savings, and increased efficiency.

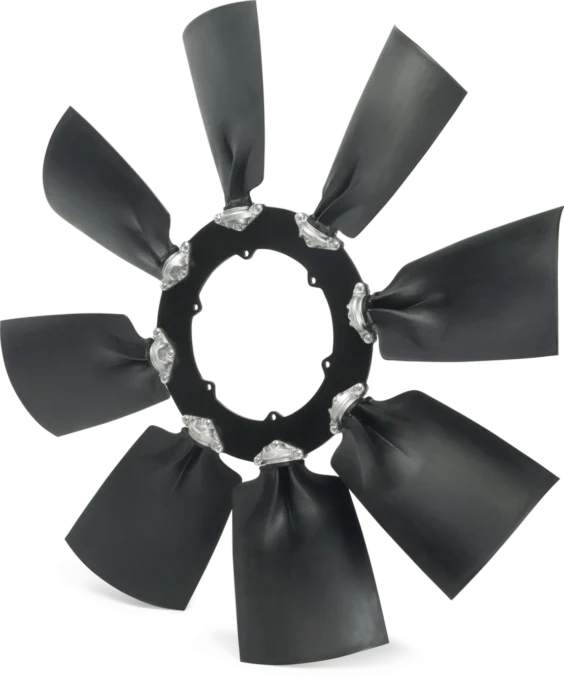

- WindShift Modular Fans: blades are clamp-mounted on a central disk, allowing optimized pitch for peak performance.

4. Engineered for Harsh Environments

- High tip-speed ratings: up to 22,000 ft/min in HTEC fans, up to 18,000 ft/min for large metal fans, ensuring durability under grueling conditions.

- Components engineered for heavy-duty duty cycles: from mining haul trucks to remote generator sets and construction equipment.

5. Expert Design Assistance = Better Results

Our experienced application engineers work directly with you to:

- Determine optimal airflow and size.

- Specify blade types and configurations.

- Select the right fan drive (variable, two-speed, on/off.)

- Ensure performance targets such as thermal requirements, noise levels, fuel use, and available horsepower are met.

Whether it’s a light truck or a high-horsepower mining rig, we design for your unique system and back it with hands-on support.

6. Real-World Impact

- Fuel economy: Variable-speed and two-speed drives reduce parasitic loss and cut fuel consumption dramatically.

- Reduced noise: Precisely controlled fan engagement helps maintain quieter operations.

- Durability & uptime: Robust components, remanufactured kits, and support services reduce maintenance and improve reliability.

Let’s Design Your Cooling SOlution

Why Choose Horton?

- 60 years of cooling innovation, recognized by export and trade awards.

- In-house R&D & mining-dedicated test labs.

- Global manufacturing & engineering footprint across the USA, Germany, China, Australia, and the UK .

- Complete front-engine systems: fans, drives, hubs, tensioners, and tailored design assistance—everything you need, all from a single trusted supplier.