Oil & Gas

Horton’s Gas Thermal Control Clutch for gas compressors reduce over-cooling, freeze-ups, and boost throughput – so compressors run efficiently year-round.

The problem

- Direct-drive fans over-cool the process gas, leading to scrubber dumps, hydrate formation, expensive maintenance, downtime, and wasted fuel.

- Fans consume up to ~10% of the engine power that could be used by the compressor to mash more gas.

Our Solution

Gas Thermal Control Clutch and Di+™ Controller

- By using our Gas Thermal Control Clutch we are able to keep engine jacket-water and compressor oil at there proper temperature ranges.

- Keep process gas temperatures in the optimal range, decoupling them from ambient temperature swings, while saving horsepower for compression even in the hottest months of the year.

Why the Oil & Gas Industry Chooses Horton?

Fewer freeze-ups & dumps

Prevent hydrate formation by avoiding over-cooling.

higher throughput

Keep heavy gases in-stream to increase BTU content and throughput (up to 20%).

Higher Efficiency

Reduced fan speed means more horsepower for compression and/or reduced fuel consumption.

Year-round stability

Automated temp maps hold process gas temps stable across all seasons and conditions.

How it works

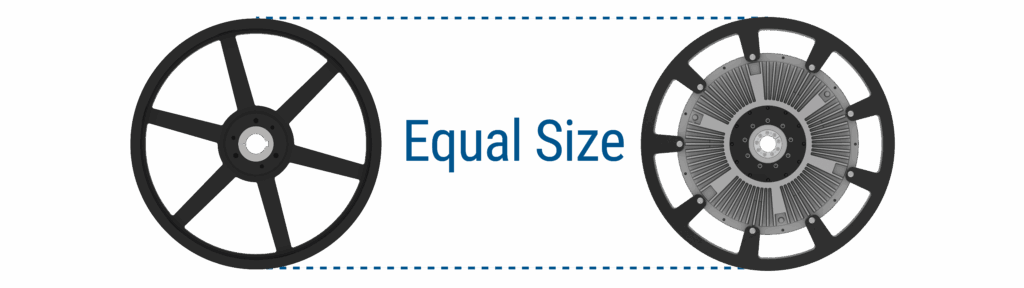

- Replace the driven fan sheave/pulley with a Horton clutch (Fits the same space claim as existing sheave/pulley for simplified field install).

- Install Gas Thermal Control Clutch controller in control panel to retrieve engine jacket water, compressor oil, and process gas temps.

- Program temperature setpoints and fan speed map.

- System will automatically modulate fan speed.

See how a viscous fan clutch, like the Gas Thermal Control Clutch, works.